From Blueprint to Reality, Insu-Built Delivers Beyond Expectations.

16115 Whatcom Road, Abbotsford, BC, Canada, V3G 0C6

Vertical ICF (Insulated Concrete Form) Envelope Building System

An Extruded PVC I-beam assembly (Rail) that holds proprietary Vertical Styrofoam Panels (VSP) along the inside and outside flanges, fixed in place with a patented retention clip. These panels can vary in thickness and density of the VSP depending on the application. as well as width, depending on construction type and client preference. The cavity that is formed between the outside and inside VSP is then filled with Helix-reinforced concrete. This creates an impermeable barrier against air, moisture, and sound penetration while providing a minimum of a 2-hour fire rating when used for perimeter, demising, and party wall assemblies. In Multi-family applications, sound transfer between units is virtually eliminated. These product components, when coupled with its ease of assembly, make it ideal for multi-family construction, while its cost-savings make it a great option for Not-For-Profit and Attainable/Affordable projects.

Our Clients

Applications

Mission

At Insu-Built, our mission is to revolutionize the construction industry by providing innovative, sustainable, and cost-effective building solutions. We are committed to delivering homes that not only withstand the test of time but also contribute to a greener and more inclusive future. Through cutting-edge technologies and a dedication to excellence, we aim to empower communities and reshape the way we build for generations to come.

Vision

Who We Are

A manufacturer and supplier of a revolutionary building product and methodology, designed to help alleviate the current supply, production, and delivery-to-market issues that currently plague the Industry’s traditional construction firms.

- Revolutionary Building System which is faster, lightweight , stronger and less expensive than conventional build systems.

- System uses recycled PVC together with high density EPS foam which forms a hollow wall cavity, insulation and vapour barrier .

- Micro-rebar (Helix) is added to the concrete in concrete truck for strength, resilience and avoids rebar tying

Product Features

Workers are easy to train and panels are assembled and snap into place. Eliminates multiple trades –no need for separate footing, foundation and framing crew. Meet exceeds current and future energy codes uses 44% less energy and 23% less energy to cool. Projects planned for Hawaii, Saudi Arabia and Eastern Canada

INSUBUILT- a Cost Effective Solution to Canada's Housing Shortage

Cost Savings with Insu-Built

Discover the substantial reduction in both skilled and overall labor costs, as Insu-Built requires 75% less skilled labor and 50% less labor overall. Explore how this efficiency opens doors to a more diverse and cost-effective labor pool.

Inclusive Construction

Explore how the product's weight reduction fosters inclusivity in construction, making it equally accessible to both men and women. Learn how the easy-to-learn assembly process broadens the labor pool, contributing to cost-effectiveness.

R20-R40 Insulative Values

Uncover the high insulative values of Insu-Built, ranging from R20 to R40 based on thickness and density. Understand how this feature contributes to energy efficiency, comfort, and reduced utility costs for homeowners.

Quick and Safe Build Anywhere

Learn how the assembly process of Insu-Built allows for installation and shoring/remediation on challenging sites, making construction possible in areas that would otherwise be inaccessible. Discover how this feature leads to quicker and safer builds.

Weathering the Storms

Explore the robustness of Insu-Built, designed to withstand 120 mph hurricanes and rainy west coast environments. Understand how the system meets all west coast seismic requirements, providing durability in the face of diverse challenges.

Quality Assurance

Gain confidence in the quality of Insu-Built, as it holds ASTM approval and is fully compliant with the National Building Code. Learn how this assurance ensures the system meets the highest industry standards.

Building a Sustainable Future

Insu-built was founded by two building and development entrepreneurs Lawrie Hooper and Richard Weldon who felt that there had to be a better way to build homes that were more sustainable, quicker to build yet stronger.

Many innovators have struggled with possible solutions including plastic homes, steel homes and concrete homes but these proved either not scaleable, not accepted by the marketplace ( homeowners and builders) or too expensive . Typically there was a disconnect between the inventors and the needs of the marketplace together with a slow to adapt culture in the building industry.

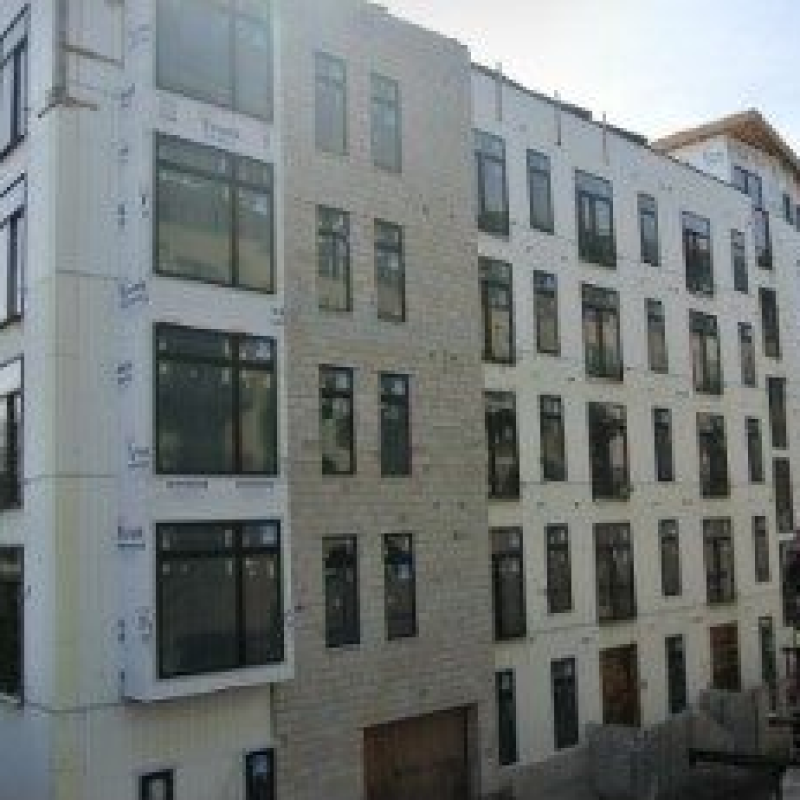

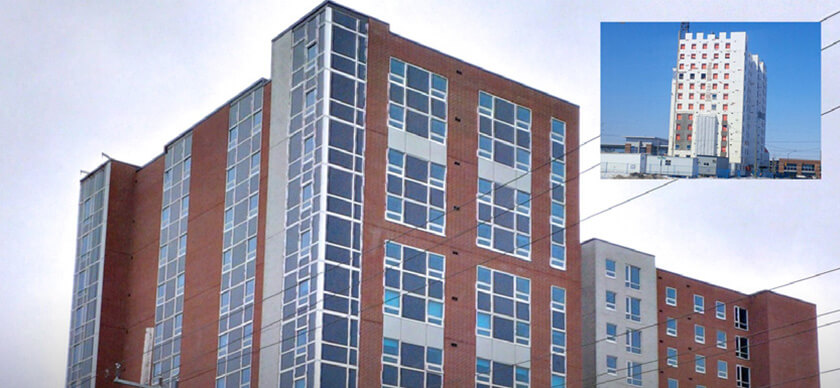

Work In Process

The Insu-Built System

Setting the Standard

Founders' Expertise

Scaled Success

Blog

Our people are dedicated to finding solutions to every challenge. That spirit makes for some great stories.

Houses built with the Insu-Built system

Frequently asked questions

These sets of questionnaires and answers by experts can help get a better understanding of our general remodeling services, timeline & process.

A. Yes it is currently patent pending with 2 applications

A. In Seattle Washington

A. Yes and we would engage local trades

Schedule Free Consultation